Description

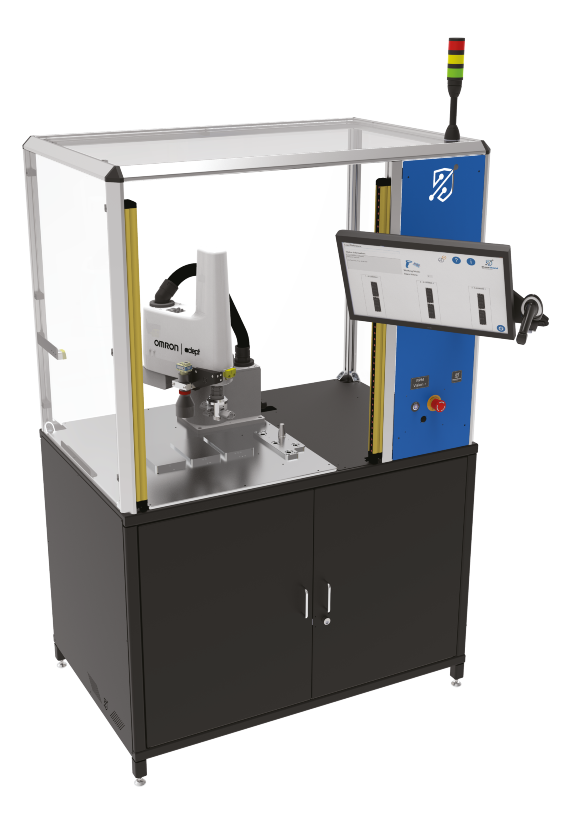

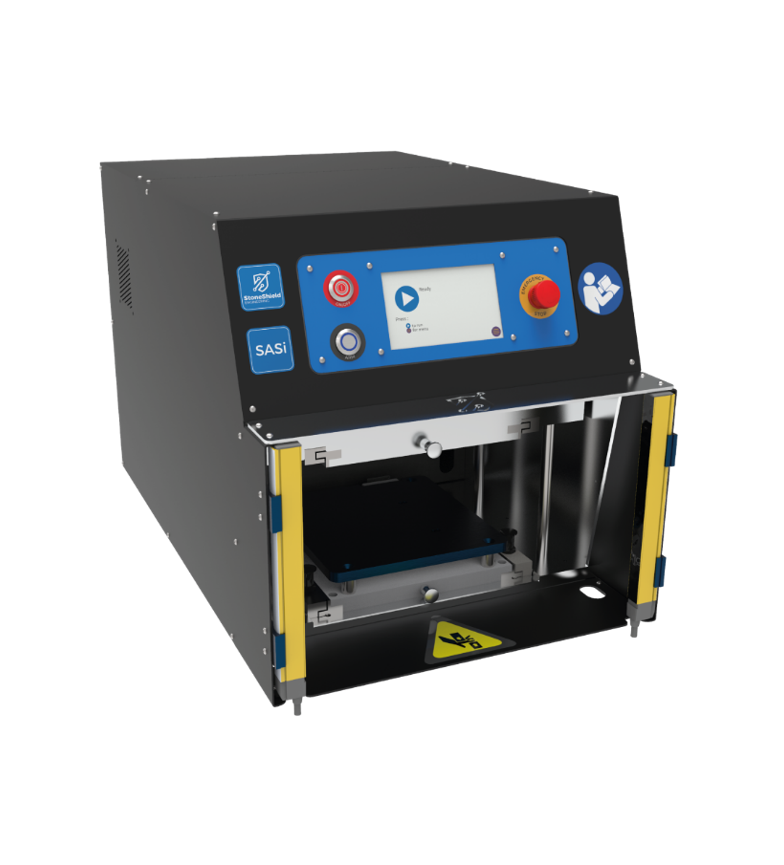

Robotic Punching Machine with Vision Inspection

The RPM Vision + is a robotic system designed to break plastic pins from connectors (punching system) in a fast and automatic way.

It uses a vision system to inspect and validate the end results of the punching process.

It ensures high quality and precise results with burr free cut and undamaged connector’s vias. since it has dedicated tools for each vias’ pattern.

It allows the processing of different connectors, in the same operation.

After the punching pattern is selected using a barcode reader or a network file (KSK server), the operator puts the connectors in the selected nests. The machine will pick the necessary tool and angle and start the punching process.

At the end of the process, the vision system will check each of the connectors to ensure that the punching process is accurate and burr free, identifying OK and NOK parts.

Combined with this flexibility, it also has a high productivity, with an average cycle of 0.7 second per pin.