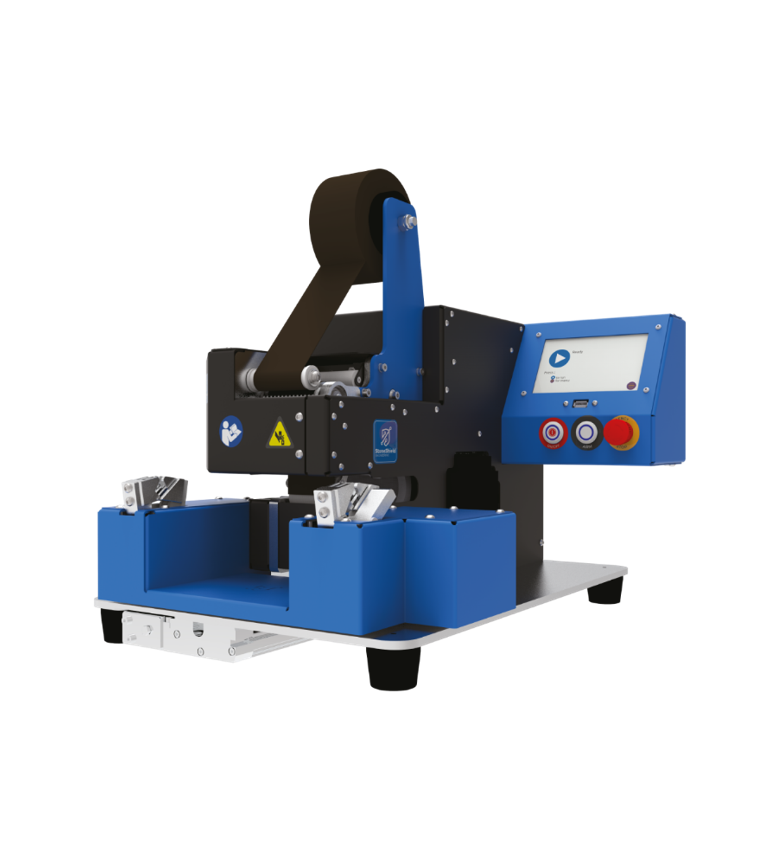

STONESHIELD FTM

Bundle diameter : 1 to 12 mm

Minimum bundle length : 180 mm

Tape width : 9 to 53 mm

Interior tape diameter : 1.5 to 3”

Tapes allowed : Any standard adhesive tape

Lenght : 454 mm (taping module) / 304 mm (control module)

Width : 375 mm (taping module) / 325 mm (control module)

Height : 390 mm (taping module) / 172 mm (control module)

Weight : 35 kg (taping module) / 8 mm (control module)

Electrical : 230 VAC @50 Hz – 1 IEC standard male socket

Consumption : 1.5 kW (peak)

Air pressure : 4.5 to 6 Bar – quick – coupler socket – 8 mm

Interface : touchscreen, barcode, buzzer and LEDs

Description

Flexible Taping Machine

The FTM – Flexible Taping Machine, is a workbench taping system for performing spot taping to insulate or bundling splices and/or wires.

It has a typical processing time of 1.8 seconds.

The FTM is an all-in-one machine, since its possible to process normal and end-splices in the same machine.

Also, it can be used with a centering system that ensures that the tape is applied always in the middle of the splice.

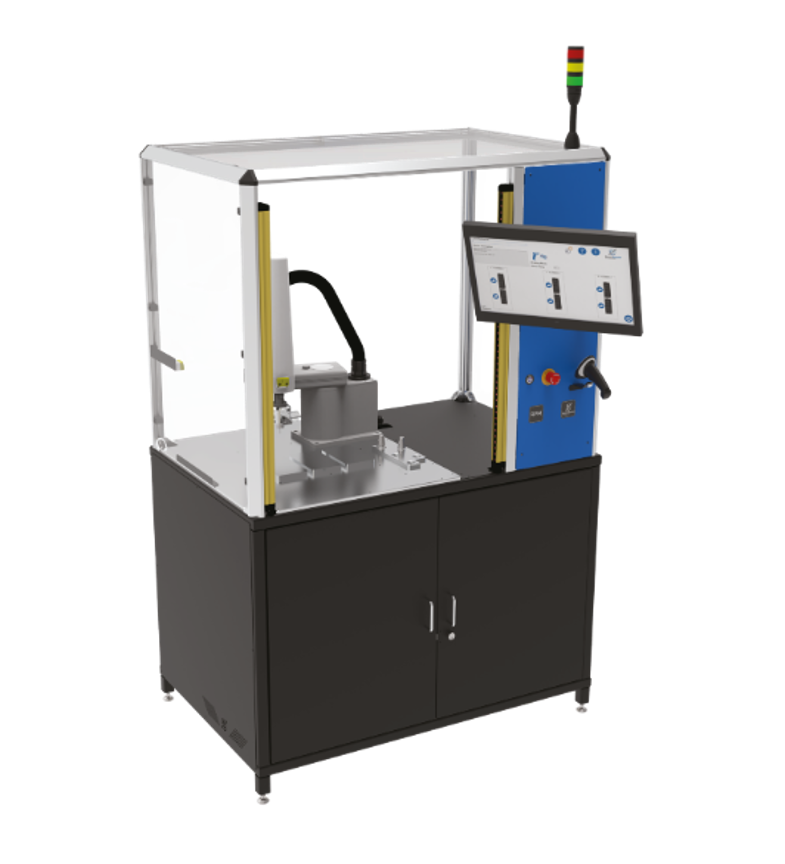

The control module is separated from the taping head, which allows for a compact design that results in a more ergonomic use and more free space in the workbench.